Chieftain Mobile Suction

Plants

for Multi Operator Industrial Cleaning & Bulk Collection.

TOXIC DUST

HANDLING

For use with toxic substances such as lead, asbestos, ceramics

and radioactive materials, Chieftain can be fitted with absolute filters of up

99.997% efficiency.

APPLICATION

The Chieftain

range of mobile heavy industrial suction

cleaner is designed to tackle a wide range of suction duties for which smaller

machines are clearly inadequate.

BULK

COLLECTION

Chieftain units can bulk dust and powder spillage from process

plant and dense materials such as catalyst & foundry sand at rates of upto 3

tons per hour.

MULTI

OPERATOR CLEANING

Chieftains can be used simultaneously by upto 6 operators,

although pipe work and hoses must be sized to suit the volume of material to

be collected and the conveying distance involved.

ADVANTAGE

- Chieftain mobile suction

cleaners are built tough enough to withstand the most arduous working

conditions of heavy industry.

- Turbine type air exhauster

consumes least power when running at maximum suction.

- Units has no tight

internal clearances and thus has minimal maintenance requirement.

- Mobility allows users to

bring the Chieftains superior suction performance wherever it is needed.

- ose diameters upto 75 mm

and lengths of 100 meters or more are quite feasible.

CENTRAL

SUCTION SYSTEMS

Chieftain units can be connected to runs of fixed pipe work to

give multi-level Central Suction service within a building.

|

|

The Chieftain with basic

filter-separator collects material into a large capacity dustbin. For heavy

materials this is the largest practical capacity for easy disposal. |

For bulky materials a

primary separator with hoppered discharge can be specified. Material can be

bagged off for dust free emptying, or discharged continuously via a rotary

valve. |

SPECIAL OPTIONS :

Chieftains are available

with petrol and propane drive in addition to the standard electrical versions.

Flameproof electrics and anti static hose are normally supplied for explosion

hazard areas. For high temperature applications, Chieftain are supplied with

suitable high temperature filters and coolers instead of conventional textile

fabric filters.

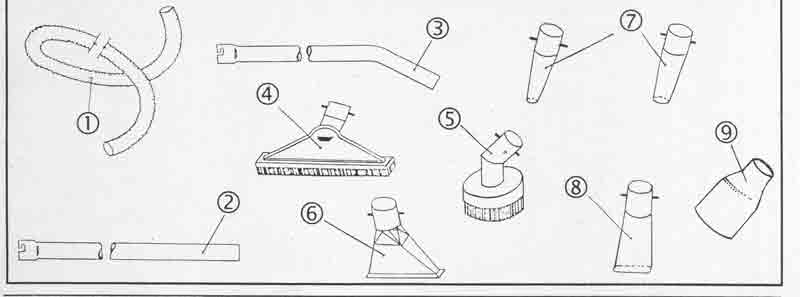

TOOLS &

ACCESSORIES :

Chieftain suction units can

be used with hoses of 40 mm, 50 mm and 75 mm bore with a range of nearly 50

special tools and fitments available. The following tools are however most

frequently specified with Chieftain machines.

STANDARD SET FOR 40 MM & 50 MM BORE

ACCESSORIES NOZZLE TOOLS

OPTIONAL ACCESSORIES

- –

75 MM BORE

- 5 mtrs long PVC reinforced PVC

flexible hose

- Fabricated aeration

nozzle

- abricated shovel type floor

clearing nozzle

- Cast Aluminium hose

connection points [snap valves]

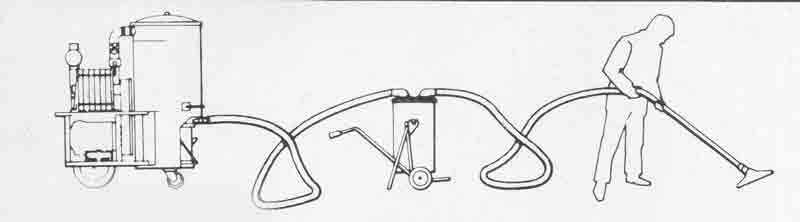

USE

WITH MOBILE INTERCEPTORS

Chieftain units can

be used with standard portable interceptors for wet or dry materials

collection. If necessary, the interceptor cam incorporate a disposable paper

bag, for dust free removal of toxic materials such as asbestos, lead, ceramics

or radioactive particles, in which case a high efficiency filter is fitted to

the suction unit’s exhaust.

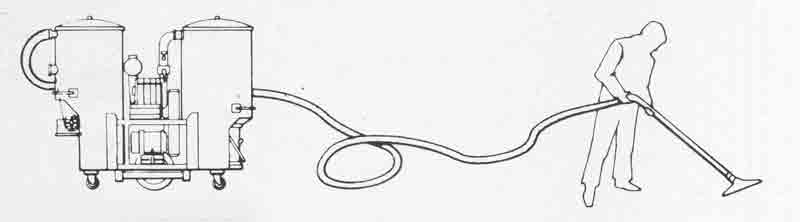

INTEGRAL PRIMARY SEPARATORS

The option of an

Integral Primary Separator hopper with hand operated discharge valve gives the

Chieftain range an added versatility and enables the easy collection and

disposal of substantial quantities of bulk material such as cement, sand,

flour etc. Fines carried over the Primary Separator are collected into the

filter dust bucket.

FIXED

PIPE WORK FOR CENTRAL VACUUM CLEANING

Chieftain suction

units can be connected to fixed pipe work to provide multi level Central

Vacuum Cleaning services in factories, grain stores, flour mills and similar

buildings. Users thus have a dual purpose, mobile unit of great versatility.

Where a completely static system is required, Doctaire-Sturtevant can be

relied upon to offer the best proposals for a purpose built plant based on

turbo air exhausters upto 100 hp supported by a wide range of standard

filters, separators and ancillary equipment.

|

|

WITH PRIMARY SEPARATOR

HOPPER TYPE 865, 675, 635 |

WITH BUCKET TYPE 860,

670, 633 |

SPECIFICATIONS

| MACHINE TYPE |

865 |

860 |

675 |

670 |

635 |

633 |

Motor HP |

20 |

20 |

10 |

10 |

7.5 |

7.5 |

| KW |

15 |

15 |

7.458 |

7.458 |

5.59 |

5.59 |

| Exhauster type/stage |

8X6 |

8X6 |

6X6 |

6X7 |

6X5 |

6X5 |

| Speed RPM |

6000 |

6000 |

6500 |

6500 |

6500 |

6500 |

| Max

suction ins WG |

120 |

120 |

118 |

118 |

100 |

100 |

| MM

WG |

3050 |

3050 |

3000 |

3000 |

2540 |

2540 |

| Max

air volume CFM |

650 |

650 |

400 |

400 |

400 | |

| M3/min |

18 |

18 |

11.3 |

11.3 |

11.3 |

11.3 |

| Hose connectors[mm] |

50 |

50 |

50 |

50 |

50 |

50 |

| |

75 |

75 |

|

75 |

75 |

| Primary separator capacity ltrs |

270 |

|

180 |

|

180 |

|

| Approx. Dia |

| Length [mm] |

2700 |

1880 |

2150 |

1600 |

1900 |

1350 |

| Width [mm] |

880 |

880 |

750 |

750 |

750 |

750 |

| Height [mm] |

1880 |

1880 |

1760 |

1760 |

1760 |

1760 |

| Nett Wt. KG |

735 |

450 |

535 |

345 |

500 |

310 |

STANDARD ON 865 & 860 MODELS

Filter: 4 sq.m, Fabric with back flush filter cleaning arrangementDust container: Removable, 112 ltrs capacity with cam lockDrive: V belt, fully guarded Starter: Push button automatic/ Star Delta

STANDARD ON 675,670,6355 & 633 MODELS

Filter: 2.7 sq.m, Fabric with back flush filter cleaning arrangement Dust container: Removable, 56 ltrs capacity with cam lock Drive: V belt, fully guarded Starter: Push button automatic/ Star Delta

In keeping our policy of continuous improvement and development, specifications should be taken as a guide only, and the company reserves the right to vary tem without prior notice

BACK TO VACUUM CLEANERS |